A. Use of Gypsum Products in Dentistry

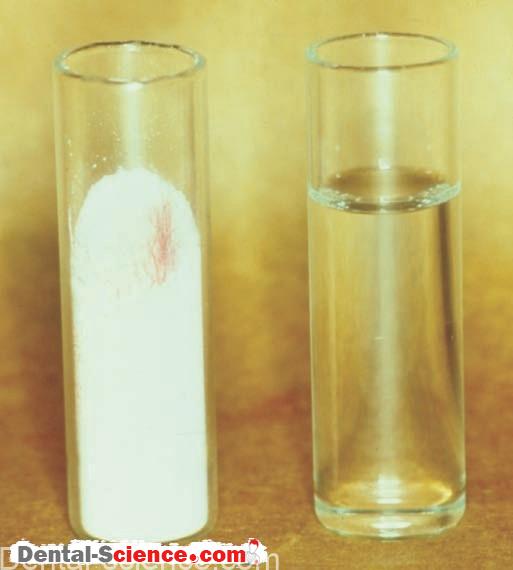

– Gypsum products are supplied as fine powders that are mixed with water to form a fluid mass that can be poured and shaped and that subsequently hardens into a rigid, stable mass.

– Gypsum products are used mainly for positive reproductions or replicas of oral structures.

– These replicas are called casts, dies, or models, and they are obtained from negative

reproductions, such as alginate impressions.

– Each replica has a specific purpose:

1. A study model is used to plan treatment and to observe treatment progress.

2. A cast is a replica on which a restoration or appliance is fabricated.

A cast is more accurate than a study model and is a replica of more than one tooth,

such as a quadrant or a full arch. It may be partially or completely edentulous

3. A die is a working replica of a single tooth. Typically, it is a removable part of a cast.

Because indirect dental restorations are fabricated on these casts or die replicas, it is

essential that the particular gypsum product be carefully manipulated to ensure

an accurate restoration.

B. Desirable Properties

– Several properties are required of a material to be used for making casts, models, or dies.

– These properties are:

1. Accuracy

2. Dimensional stability

3. Ability to reproduce fine detail

4. Strength and resistance to abrasion

5. Compatibility with the impression material

6. Color

7. Biological safety

8. Ease of use

9. Cost

– Not all gypsum products display all of these desirable properties equally.

Types of Gypsum Products

– Gypsum products are made from gypsum rock, which is a mineral found in various parts of the world.

– Gypsum rock is mined, ground into a fine powder, and then processed by heating to form a variety of products.

– Chemically, gypsum rock is calcium sulfate di hydrate (CaSO4·2H2O).

– Calcium sulfate di hydrate can also be produced synthetically.

– Pure gypsum is white, but in most deposits, it is discolored by impurities.

– Gypsum products are used in dentistry, medicine, homes, and industry.

– In homes, gypsum plaster is used to make walls; in industry, it is used to make molds.

– In this chapter, three types of gypsum products are discussed: plaster, stone,

and high-strength or improved stone.

– Chemically, all three are calcium sulfate hemihydrate.

– They are produced as a result of heating gypsum and driving off part of the water of

crystallization.

– This process is called calcination and is shown in the following equation:

CaSO4.2H2O + heat >>>> (CaSO4)2.H2O (or CaSO4.½H2O) + 1½H2O

– Plaster, stone, and improved stone differ in the physical characteristics of their powder

particles as a result of differing calcination methods.

– These differences in powder particles are responsible for their different properties, which make them suitable for various uses.

– The manufacturers add other chemicals to improve handling and various properties.

A. Plaster

– Plaster was the first gypsum product available for dentistry.

– It is manufactured by grinding the gypsum rock into a fine powder and then heating that powder in an open container.

– This direct and rapid heating in open air drives part of the water of crystallization from the crystal and shatters the crystal.

– The resulting powder consists of porous, irregular particles Plaster is the weakest and least expensive of the three gypsum products.

– It is used mainly when strength is not a critical requirement, such as preliminary casts for complete dentures and attaching casts to a mechanical device called an articulator.

– This device simulates the patient’s occlusion and mastication process.

– Plaster is usually white in color and sometimes is referred to as beta-hemihydrate or Type II.

– In the past, plaster was modified for use as an impression material by the addition of

chemicals and was called impression plaster.

B. Stone

– Stone is made from gypsum by carefully controlled calcination under steam pressure in a closed container.

– This method of calcination slowly releases the water of crystallization from the crystal

so that the resultant powder particle is more regular, more uniform in shape, and less porous compared to that of plaster.

– Stone is stronger and more expensive than plaster.

– It is used mainly in making casts for diagnostic purposes and casts for complete and partial denture construction, which require greater strength and surface hardness than that of plaster.

– The stone is usually yellow, but it can be obtained in other colors.

– It is often referred to as alpha-hemihydrate, Type III stone, or Hydrocal.

C. High-Strength or Improved Stone

– High-strength stone, or improved stone, is also made from gypsum by calcining the gypsum in a calcium chloride solution.

– This method of calcination results in a powder particle that is very dense, is cuboidal in shape, and has a reduced surface area.

– High-strength stone is the strongest and most expensive of the three gypsum products, and it is used mainly for making casts or dies for crown, bridge, and inlay fabrication.

– This material is used because high strength and surface hardness are required during the

fabrication process; the fabrication of crowns is described in the next chapter.

– High-strength stone is often referred to as Type IV stone, die stone, densite, and modified

alphahemihydrate.

– A newly developed high-strength stone with a higher compressive strength than that of Type IV stone is also available.

– It displays higher setting expansion and is referred to as Type V stone.

D. Other Types of Gypsum

– Other types of gypsum products are produced for special uses, such as fast set, mounting of casts on articulators, and impressions.

Setting Reaction

– When any of the three types of calcium sulfate hemihydrate is mixed with water,

the hemihydrate is changed back to dihydrate by the process of hydration.

– Heat is liberated, as shown by the following reaction:

CaSO4.½H2O + 1·H2O >>>>> CaSO4·2H2O + heat

– The calcium sulfate hemihydrate dissolves in the mixing water to form the dihydrate, which is less soluble than the hemihydrate.

– The calcium sulfate dehydrate precipitates out of solution as interlocking crystals, which form a hard mass.

Water/Powder Ratio

– The proportion of water to powder used to make a workable mix of a particular gypsum

product is called the water/powder ratio.

– For dental use, an excess amount of measured water above the theoretically correct amount required for hydration is always necessary.

– This excess amount is needed to make a workable mix or slurry that can be poured and shaped.

– The excess water is distributed as free water in the set mass without taking part in the

chemical reaction, and it contributes to subsequent porosity or microscopic voids in the set product.

– The proper water/powder ratio for each product depends on the physical characteristics of the powder particles.

– Plaster requires more gauging water (measured water) to wet the powder surfaces, fill the pores, and float the irregular porous particles.

– The dense particles of stone require less gauging water to float them, and their regular shape allows them to roll over one another more easily.

– High-strength stone, because of its very dense and cuboidal type of particle as well as

modifications made by the manufacturer, requires even less gauging water than stone.

– For dental use, the proper water/powder ratios (quotients) are as follows:

• For the average mix of plaster, 45–50 ml/100 g (0.45–0.50)

• For the average mix of stone, 28–30 ml/100 g (0.28–0.30)

• For the average mix of improved stone, 19–24 ml/100 g (0.19–0.24)

– This difference in the amount of measured water that is required to make a workable mix

results in different consistencies for the products when first mixed at the proper

water/powder ratio.

– Plaster is usually thin in consistency, like a ‘smoothie,’ whereas improved stone is like thick cake batter.

– Dental stone has an intermediate consistency.

– The water/powder ratio has a direct effect on the properties of each gypsum product and must be controlled for optimum results.

Setting Time

A. Definitions

– Knowledge of the setting characteristics of a gypsum product is important for proper

manipulation.

– The clinician should be aware of two time intervals in the setting process.

1. Working Time or Initial Setting Time

– Working time or initial setting time is the length of time from the start of the mix until the setting mass reaches a semi-hard stage.

– It represents the available time for manipulating the product, and it indicates partial progress of the setting reaction.

2. Final Setting Time

– Final setting time represents the length of time from the start of the mix until the setting mass becomes rigid and can be separated from the impression.

– The final setting time indicates the major completion of the hydration reaction.

B. Measurement

– Setting times are usually measured with a surface penetration test.

– Gillmore needles are commonly used for this measurement.

– When the surface of the setting product has developed sufficient strength to support the weight of the ¼-lb needle and of the 1-lb needle, the initial setting time and the

final setting time, respectively, have occurred.

– In other words, each designated setting time is reached when its respective needle no longer makes an indentation in the gypsum specimen.

– This method is somewhat arbitrary, and it is difficult to correlate directly with the setting

reaction.

– In addition, the resulting values are mainly used for comparisons of different products.

– For practical purposes in a typical dental office, loss of surface gloss can be used as

a determination of the working time; it is typically 5 to 7 minutes.

– The failure of penetration by a finger nail or dull knife would indicate relative rigidity and hardness and could be used as an indication of final set.

– Usually, a time of 30 to 45 minutes is used as a subjective criterion for the time of final set.

C. Variation in Setting Times

– The setting time of a gypsum product is controlled by the manufacturer’s particular

formulation.

– Hence, several gypsum products are available with varying setting characteristics.

– Either a fast-setting or a slow-setting product can be purchased.

– Sometimes, it may be necessary to modify the setting time of a gypsum product in the dental office.

– Increased and decreased setting times may be obtained in the following ways:

1. Increased Setting Time (A Slower-Setting Product)

(A) Decreased mixing.

(B) Higher water/powder ratio (creates a thinner mix).

(C) Addition of certain chemicals called retarders. A commonly used retarder is borax.

2. Decreased Setting Time (A Faster-Setting Product).

(A) Increased mixing (the longer the mixing time, the shorter the setting time).

(B) Lower water/powder ratio (creates a thicker mix).

(C) Addition of certain chemicals called accelerators.

– A commonly used accelerator is potassium sulfate.

– Other chemicals can be used, but their effect on the setting time depends on concentration and other factors.

– Improper storage and use of gypsum products can also change the setting characteristics.

– Because water is essential for the setting reaction, any moisture that inadvertently comes in contact with the product can change the setting time.

– Thus, gypsum products should be stored in airtight containers to prevent any

uptake of water resulting from high relative humidity.

– As a result, pre-weighed packages have become popular for some gypsum products.

– The first indication of moisture contamination is faster setting of the product.

– If the contamination continues, slower setting occurs.

Setting Expansion

– All gypsum products expand externally on setting.

– Plaster expands the most, at 0.2% to 0.3%.

– Stone expands 0.08% to 0.10%. High-strength stone expands the least, at 0.05% to 0.07%.

– Theoretically, a contraction on setting can be calculated; however, the growing crystals of the gypsum push against each other and cause an outward crystal thrust.

– In turn, this thrust causes an external expansion with resulting internal porosity in the set mass.

– A minimal setting expansion is desirable to achieve accurate dimensional reproduction for most casts and dies.

– Manufacturers modify most gypsum products that are used for casts and dies to provide for minimal expansion.

– They do this by the addition of chemicals, which also control the setting characteristics.

– Thus, a particular gypsum product has both the setting time and expansion characteristics controlled by the manufacturer.

– The setting expansion can be controlled by manipulating variables.

– A thicker mix and increased spatulation will cause an increase in the amount of setting

expansion; a thinner mix and decreased spatulation will cause a decrease in the amount of setting expansion.

– In most dental offices, however, there is little need to change the expansion characteristics of gypsum products.

– If gypsum materials are immersed in or come in contact with water during the setting

process, the setting expansion increases.

– This is called hygroscopic expansion, and it can be used to increase the setting expansion of casting investments.

– Although small, hygroscopic expansion is approximately twice as great as the normal setting expansion.

– Therefore, to prevent an inadvertent increase in size, routine casts should not be immersed in water during setting.

Strength

– The strength of the gypsum product is usually measured in terms of crushing or compressive strength.

– As expected from the setting reaction, strength develops rapidly during the first 30 to 45 minutes as hydration is completed.

– The strength depends on the porosity of the set material, and the porosity relates to the

water/powder ratio necessary to make a workable mix.

– Plaster, which requires the most gauging water to make a fluid mix, is the weakest in strength, with improved stone being the strongest and stone being intermediate between the two.

– The 1-hour strengths of gypsum products are listed in Table below .

– The presence or absence of excess free water also affects strength.

– Two types of strength are recognized: wet strength and dry strength.

A. Wet Strength

– The wet strength is the strength that is measured when the sample contains some or all of the water in excess of the theoretical amount required for hydration.

– This is the typical condition after setting.

– The material feels wet to the touch for many hours.

B. Dry Strength

– The dry strength is the strength that is measured when the excess water is not present in the sample.

– The dry strength may be two or more times the wet strength.

– Usually, the cast must sit in a dry environment overnight to approach these values.

C. Factors Affecting Strength

– The strength of a particular product depends on the water/powder ratio; thicker mixes will increase the strength within limits, and thinner mixes will decrease the strength.

– However, extremely thick mixes, particularly those of stone and improved stone, are heavy in consistency and can cause distortion of the impression as well as entrapment of air voids.

– Extremely thin mixes will cause a decrease in strength.

– Therefore, it is a good practice to follow the manufacturer’s recommended water/powder

ratio for optimum strength and consistency properties.

Surface Hardness

– The surface hardness is related to the compressive strength, but reaches its maximum value more rapidly because the surface is the first to dry.

– The greatest surface hardness occurs when the product reaches its dry strength, which many times is not realized under practical conditions.

– Casts and dies should be allowed to set for 1 to 2 hours, or preferably overnight or longer,

before beginning subsequent laboratory procedures.

– The surface hardness of set gypsum is not as high as desired.

– Use of a commercial hardening solution in place of water may increase the hardness and

improve the abrasion resistance.

Dimensional Stability

– The dimensions of a hardened or set gypsum cast are relatively constant under ordinary

conditions of room temperature and humidity; however, gypsum is slightly soluble in water.

– Occasionally, it is necessary to soak a cast in water for a laboratory procedure.

– If the cast is soaked in water for prolonged periods of time, the surface may be dissolved away.

– If the cast must be soaked in water, the water should be saturated with gypsum to prevent erosion of the surface.

– The safest way to soak a cast is to place it in a water bath containing particles of gypsum to provide a saturated solution of calcium sulfate at all times.

Technique of Use

– The technical use of gypsum products is relatively simple, requiring only a mixing bowl,

mixing spatula, room-temperature water, and the appropriate gypsum product.

– As mentioned earlier, the water and powder must be proportioned accurately for optimum properties to be obtained.

– The measuring and mixing technique can be summarized as follows.

A. Measuring the Water

– The water is usually dispensed by volume in a graduated cylinder because 1 g of water has

a volume of very close to 1 ml.

B. Measuring the Powder

– The powder can be weighed in grams with a simple balance or scale.

– Use of a dietetic scale is a convenient method for weighing the powder.

– First, the water is added to the mixing bowl and it is placed on the scale.

– Second, the scale is tared (reading is set to zero).

– Finally, the powder is added to the bowl with a suitable scoop until the desired weight of powder has been added.

– Volume dispensers may also be used.

– Volume dispensing of the powder is not as accurate, however, because of the

varying packing effect on the powder.

– Weighing with the scale is a simple and convenient method to ensureaccurate proportions.

– Pre-weighed envelopes are now available that control the weight of the powder to provide accuracy and reduce both wasted powder and time required.

C. Adding Powder and Water

– The preferred method of mixing is to add the measured water into the mixing bowl first,

followed by gradual addition of the pre-weighed powder.

– The guesswork of repeatedly adding water and powder to achieve the proper consistency is to be avoided even though it is a common practice.

– It can result in low strength and inconsistent expansion.

D. Mixing

1. Hand Mixing

– Hand mixing is usually done in a flexible plastic or rubber bowl with a stiff-bladed spatula to combine the powder and water.

– The mix should be smooth, homogeneous, workable, and free of air bubbles.

– A minimum of air inclusion in the mixed product is desirable to prevent surface bubbles and internal defects.

– Mixing is usually accomplished with a wiping motion against the sides of the bowl

(to eliminate lumps and air bubbles).

– Use of a dental vibrator will reduce bubbles in the mix.

– A smooth, homogeneous mix should be obtained in approximately 1 minute.

– A whipping motion should be avoided.

2. Vacuum Mixing

– Often, mixing is done mechanically with a vacuum mixing and investing machine.

– This provides a gypsum mix that is free of air bubbles and is homogeneous in consistency.

– Many devices are available that will mix gypsum products mechanically with or without

vacuum.

– They are used when the elimination of voids and surface bubbles is critical.

E. Filling the Impression

– When filling the impression, the gypsum mixture needs to flow slowly “ahead of itself” to

prevent the entrapment of air.

– This is usually accomplished with a dental vibrator.

– This is particularly important when filling elastomeric impressions, which in many instances are water repellent.

– Vibrating the mix after mixing can also be used to bring air bubbles to the surface.

– Although relatively simple, manipulation of gypsum products requires careful attention to

detail for accurate results.